AUTO Series Automatic Booster Pump

Application

These pumps are suitable for pumping clean water and fluids which

are not chemically aggressive to the pump components.

They are extremely reliable ,economical and simple to use

being particularly suitable for domestic applications medium-sized surge tanks, watering gardens, etc.

These pumps should be installed in a covered area,

protected against the weather.N.B.it is always advisable to install a foot valve or non-return valve on the suction opening.

Working conditions

Max temperature of Fluid up to +60℃

Max Ambient Temperature up to 40℃

Suction lift up to 8m

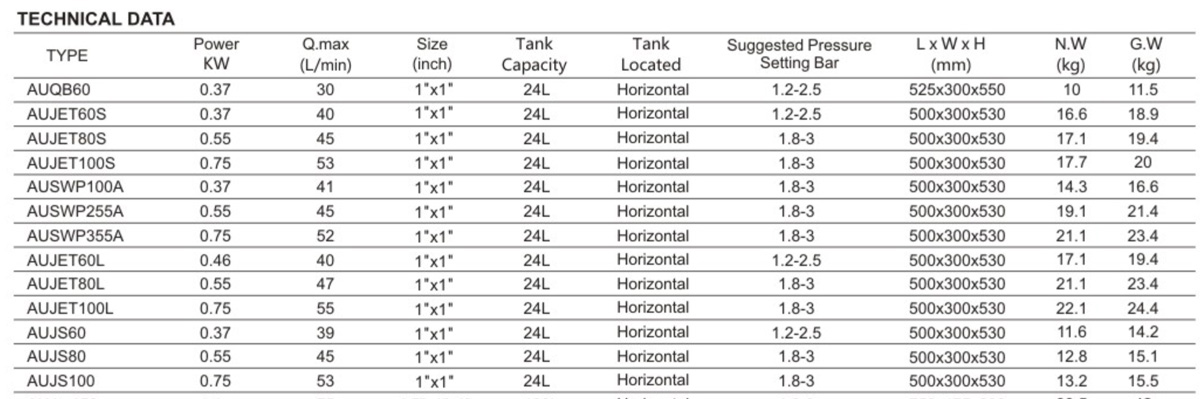

Technical data

Technical Description

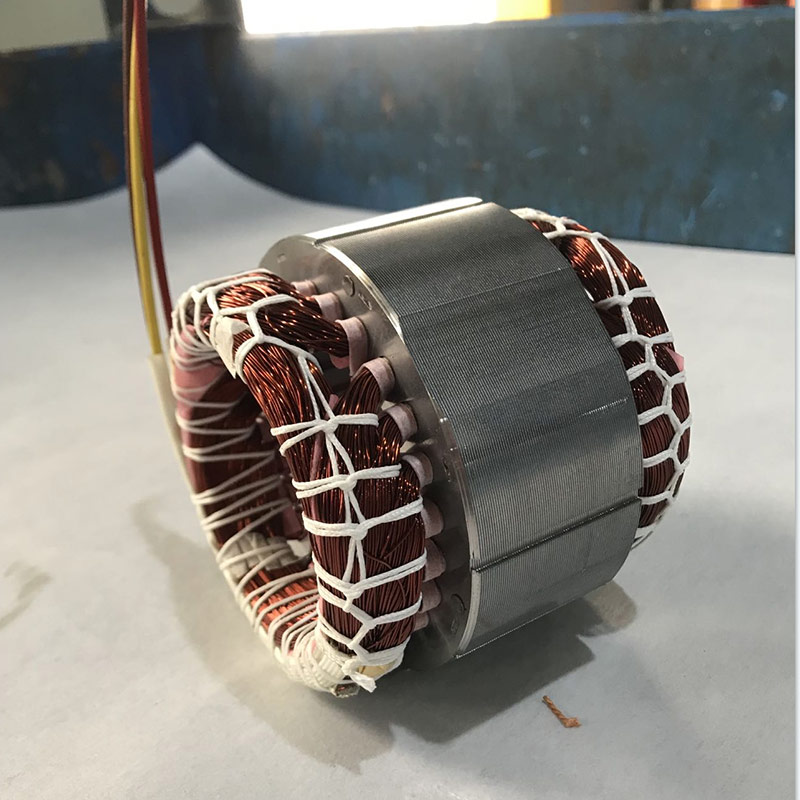

1. motor

100% copper winding coil, machine wiring,new material stator,low temperature rise,stable working

(aluminum winding coil for your choice available,different stator length for your choice also)

2. Impeller

Brass material

Stainless steel material

Aluminum material

Plastic material

3. Rotor and shaft

Surface moisture proof ,anti rust treatment

Carbon steel shaft or 304 stainless steel shaft

Exploded View

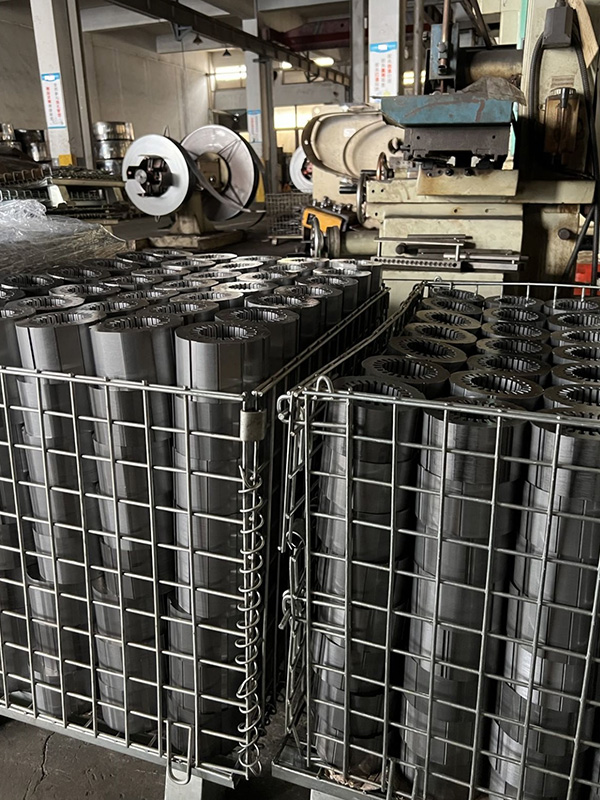

Production line

Quality control

heed the ISO 9001 quality management system. From conception to testing to approval prior to acceptance, from a sample to a batch purchase The materials from our vendors are inspected before entering our warehouse. to create a quality control plan and operation instructions. It was discovered by test equipment during production, and a second spot check was performed before to distribution.

Installation instruction

The area where the pumps are located needs to be well-ventilated and dry, with an ambient temperature of no more than 40°C (Fig.A). Secure the pump with the correct bolts on a solid, flat surface to prevent vibration. The pump must be positioned horizontally in order for the bearings to operate properly. The diameter of the intake pipe cannot be smaller than that of the intake motor. If the intake height is greater than 4 meters, use a pipe with a larger diameter. The diameter of the deliverypipe must be chosen to correspond to the flow rate and pressure required at the takeoff points. The intake pipe must be slightly angled up toward the intake mouth in order to prevent the formation of air locks (Fig.B). Make sure the intake pipe is sealed and completely immersed.

Packing

a wooden box, a honeycomb box, or a colored inner carton box.

Transportation

Priority loading in the ports of Ningbo, Shanghai, and Yiwu.

Full container of bulk goods

Samples

Discuss to offer free sample, some may be charged first,if you place a formal order, consider a charge refund.

Could check sample shipment by land, sea, or even air as you like.

Payment term

T/T term: 20% deposit in advance, 80% balance against copy of bill of lading

L/C term: prefer L/C at sight

D/P term, 20% deposit in advance, 80% balance of D/P at sight

Credit insurance: 20% advance deposit first, 80% balance OA 60 days by confirmation from the insurance company.

Warranty

The product warranty period is 13 months (calculated from the date of bill of lading). According to the relevant vulnerable parts and components, if there is a manufacturing quality problem belonging to Supplier during the warranty period, Supplier shall be responsible for providing or replacing the repair parts after the joint identification and confirmation of both parties. The quotation of conventional products does not include any proportion of accessories. During the warranty period, according to the actual feedback, we will negotiate to provide vulnerable parts for maintenance, and some parts may need to be purchased with compensation. Any quality problems can be reported for research and negotiation